Unlocking the Secrets of Ultra-Smooth Coatings – PTN SDA

In the powder coating industry, a good flow agent can significantly enhance the performance of powder coatings, resulting in a smoother coating surface and greatly improving transfer efficiency. Now, let’s introduce a revolutionary powder additive – PTN SDA Super Dry Agent. It can markedly improve the performance of powder coatings, leading to a smoother coating surface and a substantial increase in transfer efficiency. Let's explore its unique features!

1. Introduction to Super Dry Agent

Product Description:

PTN SDA (Super Dry Agent) is a super dry agent that can be used for post-blending. It can significantly improve the electrostatic charging properties of powder, enhance transfer efficiency. At a dosage of 0.1%, it effectively improves film thickness uniformity during spraying and enhances surface smoothness; at 0.3%, it noticeably mitigates piling in textured coatings; at 0.2%, it effectively reduces gun clogging and spitting with metallic powders; at 0.5%, it effectively addresses poor leveling caused by high metallic pigment content. It can be added in appropriate amounts to formulate thin-film powders (requires suitable resin content and particle size control).

Physical Properties:

Appearance | White free-flowing powde |

Density (KG/I) | 0.12 |

Particle Size (NM) | 10-30 |

Product Features:

Broad Compatibility: Suitable for various powder coating systems. Can improve transfer efficiency, increase sprayable area, and adjust surface smoothness.

Easy Application: Added to powder coatings, it facilitates spraying, offering comprehensive improvement especially for coating hard-to-reach areas (Faraday cage areas) on workpieces.

Suitable for Thin-Film & Metallic Powders: Particularly suitable for 30-50 micron thin-film and metallic powder coatings. Effectively prevents gun clogging and spitting, improves powder atomization and flowability, and significantly enhances powder fluidization.

Prevents Caking: Used in high-temperature summer environments, it can effectively prevent powder caking and agglomeration, thereby improving production efficiency.

Post-Blend Usage: PTN SDA can be used in the post-blending stage of powder coating production, conveniently addressing issues like powder agglomeration and uneven transfer efficiency.

Improves Charging: Significantly improves the electrostatic charging properties of powder, boosting transfer efficiency.

Enhances Leveling: Can significantly improve spraying uniformity and enhance coating surface smoothness.

Wide Application Range: Especially suitable for the metallic powder field, effectively solving problems like uneven film thickness and poor leveling.

2. Practical Problems Solved by PTN SDA

Hard-to-Reach Area Coating: PTN SDA can significantly improve coating effectiveness in hard-to-reach areas (Faraday cage areas) of various workpieces, ensuring uniform coating coverage.

Leveling Issues: Different substrate materials may exhibit poor leveling during the heating process. PTN SDA can effectively resolve this issue.

Reduced Metallic Powder Usage: Using PTN SDA can lower the required amount of metallic powder while improving coating appearance and resolving issues like spitting and uneven color (mottling).

More Uniform Metallic Powder Dispersion: PTN SDA improves the dispersibility of metallic powders, leading to more even metallic particle alignment and further enhancing the aesthetic appeal of the coating.

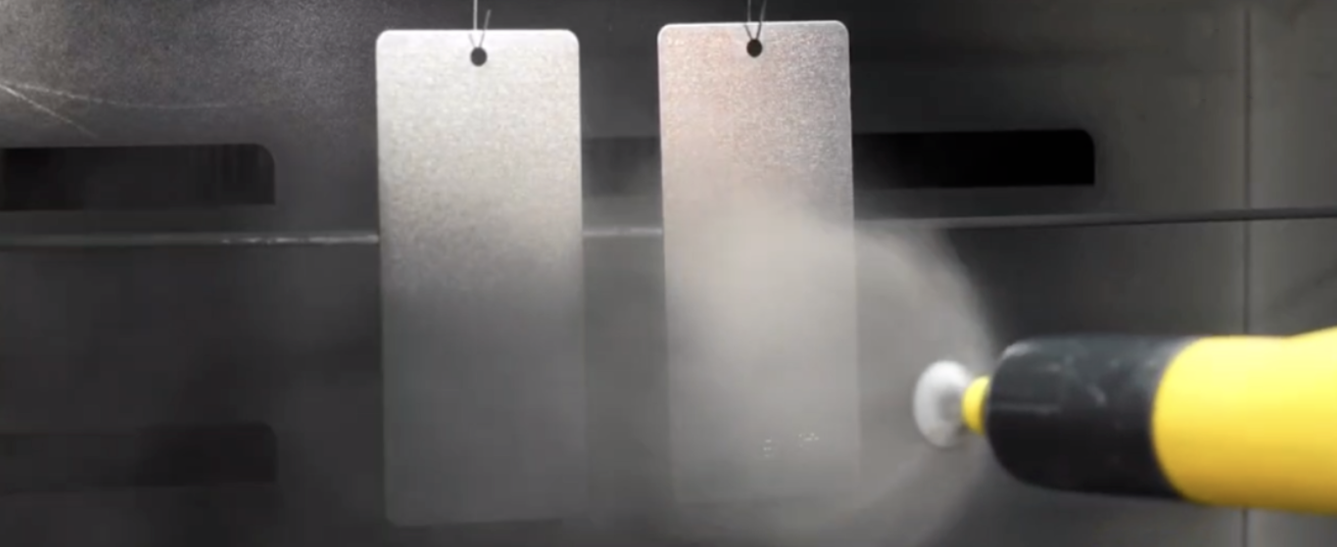

Superior Atomization: Compared to alumina-based flow agents, PTN SDA demonstrates superior performance in terms of atomized powder output.

Reclaimed Powder Reuse: PTN SDA is suitable for use in reclaimed powder recycling processes. It improves atomization and solves problems of uneven film thickness and poor leveling.

Resolving Customer Complaints: PTN SDA can effectively resolve various customer complaints related to powder coating application, improving customer satisfaction.

Textured Powder Issues: PTN SDA also provides excellent improvement for textured powders regarding spitting, edge burning, and piling problems.

Thin-Film Application: At an addition rate of approximately 0.5%, PTN SDA can be used for 30-50 micron thin-film applications, ensuring uniform film thickness without affecting leveling and panel appearance.

Recent Post